Understanding the Science Behind Mixer Pumps: Essential Guide for Efficient Fluid Management

In the realm of fluid management, the importance of Mixer Pumps cannot be overstated. These essential devices play a pivotal role in various industries, including construction, agriculture, and wastewater treatment, facilitating efficient mixing, transporting, and managing different types of fluids. According to a recent industry report by MarketsandMarkets, the global mixer pump market is projected to grow significantly, reaching an estimated USD 1.2 billion by 2025, driven by increasing demand for efficient fluid handling solutions. As processes become more complex and the need for precision in mixing escalates, understanding the science behind Mixer Pumps becomes crucial for professionals seeking to optimize their operations. This guide serves as an essential resource for comprehending the mechanisms, applications, and advantages of Mixer Pumps, ensuring that stakeholders can make informed decisions to enhance operational efficiency and productivity.

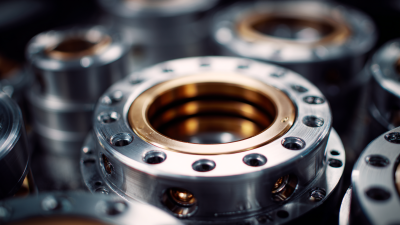

Key Components of Mixer Pumps and Their Functions

Mixer pumps are essential tools in various industries for efficient fluid management, relying on several key components that play specific roles in their operation. The heart of a mixer pump is the motor, which provides the power necessary to drive the mixing and pumping processes. Depending on the application, these motors can vary in capacity and design, ensuring optimal performance for different viscosities and fluid types.

Another crucial component is the mixing chamber, where the actual blending of fluids occurs. The design of this chamber is engineered to promote thorough mixing while maintaining flow efficiency. Within the chamber, agitators or impellers create turbulence, ensuring that all ingredients are uniformly integrated before being discharged. Additionally, the housing of the mixer pump often incorporates features like discharge ports and safety valves, which together facilitate smooth operation and prevent backflow or pressure issues, further enhancing the overall efficiency of fluid management systems.

The Role of Fluid Dynamics in Mixer Pump Efficiency

Fluid dynamics plays a crucial role in the efficiency of mixer pumps, influencing how effectively they blend and transfer fluids. Understanding the principles of fluid dynamics can help operators optimize their systems to achieve better performance. Key factors such as viscosity, flow rate, and pressure differentials impact how fluids interact within the pump. By grasping these concepts, users can make informed decisions about the design and operation of their mixer pumps to enhance fluid management.

**Tips:** Ensure that the viscosity of the fluid being pumped is compatible with the mixer pump's specifications. This compatibility is vital for minimizing turbulence and maximizing mixing efficiency. Additionally, regularly monitor flow rates and adjust pump settings accordingly to maintain optimal performance.

Achieving efficient fluid management also involves selecting the right impeller design and operating speed. The shape and size of the impeller can significantly affect the flow patterns within the pump. By conducting tests and adjusting these parameters, operators can find the ideal balance that minimizes energy consumption while maximizing mixing effectiveness.

**Tips:** Experiment with different impeller designs and speeds during initial tests to identify which combination yields the best results for your specific application. Documenting these findings will be valuable for future operations and adjustments.

Understanding the Science Behind Mixer Pumps: Essential Guide for Efficient Fluid Management - The Role of Fluid Dynamics in Mixer Pump Efficiency

| Pump Type | Fluid Type | Flow Rate (L/min) | Efficiency (%) | Power Consumption (kW) |

|---|---|---|---|---|

| Hydraulic Mixer Pump | Water | 150 | 85 | 5.5 |

| Electric Mixer Pump | Oil | 120 | 90 | 7.0 |

| Submersible Mixer Pump | Slurry | 80 | 80 | 3.5 |

| Gear Mixer Pump | Viscous Liquids | 60 | 92 | 4.2 |

| Centrifugal Mixer Pump | Chemicals | 200 | 88 | 6.0 |

Best Practices for Maintaining Mixer Pumps for Optimal Performance

Maintaining mixer pumps in optimal condition is crucial for efficient fluid management across various industrial applications. Just as the performance metrics of rocket engines depend heavily on specific impulse for operational efficiency, the lifespan and functionality of mixer pumps hinge on best practices in maintenance. Regular inspections and timely servicing can greatly boost a mixer pump's performance, reducing the likelihood of failures and extending service life by up to 20%, as noted by several industry reports.

Moreover, implementing filter systems to prevent debris accumulation not only enhances the pump's overall efficiency but also minimizes wear and tear, leading to significant cost savings in operations. A recent market analysis predicts that the global market for solar-powered pumps will grow from approximately $139.98 million in 2025 to $403.81 million by 2033, reflecting a robust compound annual growth rate of 14.16%. This growth emphasizes the increasing reliance on efficient fluid management solutions, highlighting the importance of maintaining equipment like mixer pumps to meet rising demand effectively.

Common Applications of Mixer Pumps in Various Industries

Mixer pumps are vital tools in numerous industries, adept at handling a wide variety of applications that require efficient fluid management. In the construction industry, for example, mixer pumps are frequently used to transport concrete and other viscous materials seamlessly to various locations on-site. Their powerful motor and mixing capability ensure that the concrete remains uniform and workable, essential for structural integrity in building projects.

In the pharmaceutical sector, mixer pumps play a crucial role in the creation of liquid medications and therapeutic solutions. They guarantee consistent mixing of active ingredients, providing uniform dosage and efficacy. Moreover, in the food and beverage industry, these pumps are utilized for blending ingredients, pasteurization processes, and ensuring hygiene standards. The versatility of mixer pumps across these industries highlights their importance in improving production efficiency and maintaining quality standards.

Innovative Technologies Enhancing Mixer Pump Effectiveness

Mixer pumps are becoming increasingly vital in various industries due to their ability to efficiently manage fluids. The integration of innovative technologies has significantly enhanced their effectiveness, allowing for better mixing and transport of diverse materials. Advanced software controls, for instance, enable precise monitoring and adjustment of pump performance, ensuring optimal operation and minimizing waste. Additionally, the use of sensors aids in real-time data collection, allowing for quicker decision-making and troubleshooting.

Mixer pumps are becoming increasingly vital in various industries due to their ability to efficiently manage fluids. The integration of innovative technologies has significantly enhanced their effectiveness, allowing for better mixing and transport of diverse materials. Advanced software controls, for instance, enable precise monitoring and adjustment of pump performance, ensuring optimal operation and minimizing waste. Additionally, the use of sensors aids in real-time data collection, allowing for quicker decision-making and troubleshooting.

Tips: Always consider the specific viscosity and density of the fluids being mixed, as these factors can impact the pump's efficiency. Regular maintenance and calibration of your mixer pump can prevent downtime and extend its lifespan. Furthermore, investing in high-quality components can make a substantial difference in performance, leading to more streamlined fluid management processes.

Modern mixer pumps are now incorporating smart technologies such as IoT connectivity, which allows for remote monitoring and control. This capability not only enhances operational efficiency but also significantly reduces the risk of costly oversights. By leveraging these advancements, businesses can achieve greater consistency in product quality and reduce operational costs, positioning themselves competitively in the marketplace.

Related Posts

-

What Makes a Mixer Pump Essential for Modern Industry

-

Unlocking the Benefits of Efficient Tractor Hydraulic Pumps for Your Agricultural Needs

-

China's Smart Manufacturing Leading Global Sales of Quality Hydraulic Parts

-

Exploring the Unique Features and Applications of the Best Hyd Pumps: An In-Depth Look at Alternative Types

-

Top Strategies for Maximizing Efficiency with the Best Hydraulic Machine in Your Industry

-

Exploring the Top Examples of Best Hydraulic Motors for Global Buyers