Maximizing Efficiency: The Unmatched Benefits of Best Pumps and Motors for Global Supply Chains

In today's fast-paced global supply chains, maximizing efficiency is essential for staying competitive in the marketplace. One of the key components that play a significant role in achieving this efficiency is the use of advanced pumps and motors. These critical tools not only facilitate the smooth operation of various industrial processes but also significantly enhance productivity and reduce operational costs. As industries increasingly seek alternatives to traditional mechanisms, the focus has shifted towards optimizing pumps and motors to meet the rigorous demands of global logistics and supply chain management. This blog will explore the unmatched benefits of selecting the best pumps and motors, delving into how these alternatives can transform supply chain operations by improving performance, reliability, and responsiveness, ultimately leading to a more streamlined and effective business model.

The Role of High-Quality Pumps and Motors in Enhancing Supply Chain Performance

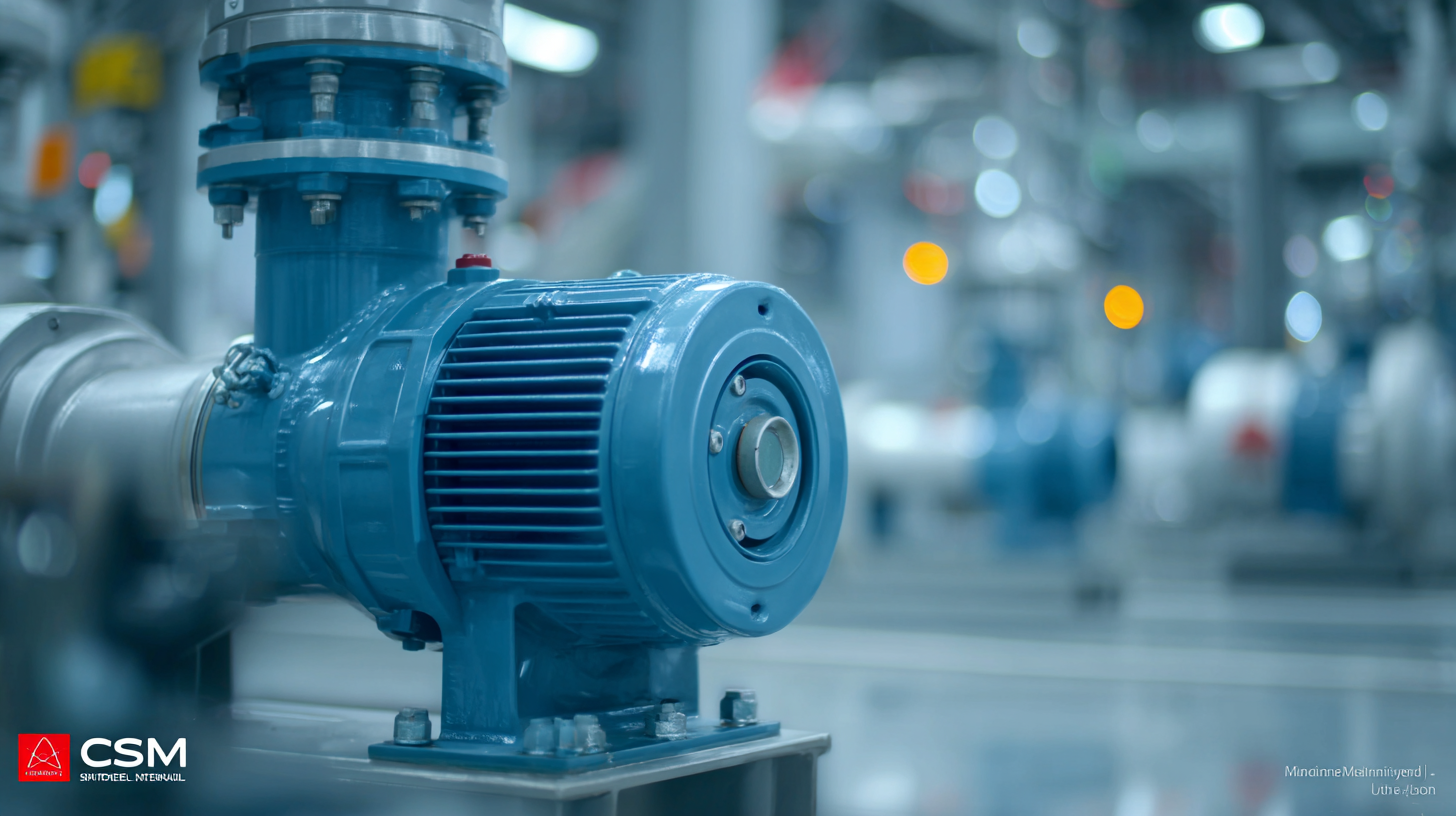

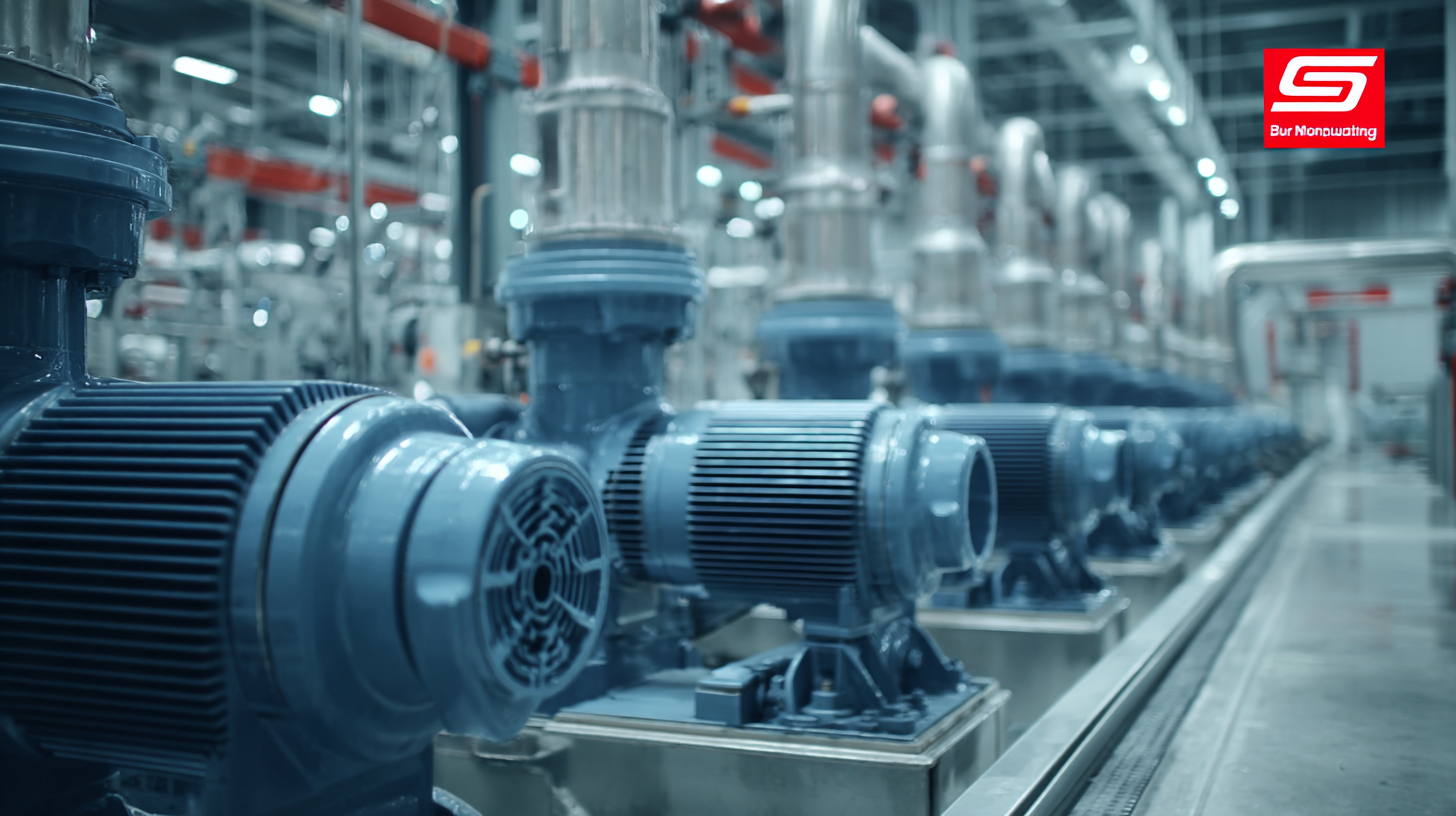

High-quality pumps and motors play a pivotal role in enhancing the efficiency and reliability of global supply chains. These components are essential for the seamless transport of liquids and materials in various industries, directly impacting productivity and performance. When supply chains integrate superior pumps and motors, they benefit from reduced downtime, as these high-quality components are built to last and require less frequent maintenance. This increased reliability ensures that production schedules are met and that the supply chain operates smoothly, ultimately leading to higher customer satisfaction.

Furthermore, the use of advanced pumping and motor technologies can lead to significant energy savings. By optimizing energy consumption, companies not only cut costs but also reduce their environmental footprint—a critical factor in today’s sustainability-driven market. Enhanced energy efficiency directly translates to lower operational costs and a more sustainable supply chain, allowing businesses to allocate resources more effectively. As a result, investing in best-in-class pumps and motors is not just a choice; it's a strategic necessity for companies aiming to thrive in a competitive landscape.

Maximizing Efficiency: The Unmatched Benefits of Best Pumps and Motors for Global Supply Chains

| Metric | Before Implementation | After Implementation | Improvement (%) |

|---|---|---|---|

| Overall Equipment Effectiveness (OEE) | 65% | 85% | 30% |

| Energy Consumption (kWh) | 12000 | 9000 | 25% |

| Downtime (hours/month) | 40 | 10 | 75% |

| Maintenance Costs ($) | 5000 | 3000 | 40% |

| Productivity Rate (%) | 75% | 90% | 20% |

Innovative Technologies Driving Efficiency in Chinese Manufacturing

Innovative technologies are revolutionizing the efficiency of Chinese manufacturing, playing a crucial role in optimizing global supply chains. A report by the McKinsey Global Institute states that the integration of advanced manufacturing technologies could increase productivity in China by up to 30% over the next decade. This surge in efficiency is largely driven by the adoption of best pumps and motors, which are vital components in various manufacturing processes. These technologies not only enhance operational performance but also reduce energy consumption, aligning with the country's goals for sustainability.

Furthermore, the implementation of smart manufacturing solutions, as highlighted by a study from the China Academy of Information and Communications Technology, indicates a significant uptick in supply chain responsiveness. Technologies such as IoT-enabled pumps and energy-efficient motors are pivotal in achieving real-time monitoring and management, which can lead to a 10-15% reduction in operational costs. As Chinese manufacturers continue to embrace these innovations, they are not only boosting their competitiveness but also setting a benchmark for global operational efficiency in supply chains.

Cost Reduction Strategies Through Advanced Pump and Motor Solutions

In the ever-evolving landscape of global supply chains, organizations are continually seeking innovative ways to enhance efficiency and reduce costs. One of the most impactful strategies is adopting advanced pump and motor solutions. According to a report by the U.S. Department of Energy, replacing outdated pumps and motors with high-efficiency models can lead to energy savings of up to 30%. These improvements not only decrease operational costs but also contribute to a more sustainable business model.

Tip: Conduct a comprehensive energy audit to identify inefficiencies in your current pumping and motor systems. This will help in determining the potential savings and justify the investment in new technology.

Moreover, integrating state-of-the-art pumps and motors can streamline processes, reducing maintenance downtime and increasing reliability. A study from the European Union suggests that implementing smart pumps with IoT capabilities can enhance performance management, allowing companies to respond swiftly to fluctuating demands. This adaptability not only improves workflow but also ensures continuous cost reduction.

Tip: Regularly update your supply chain strategies to include the latest advancements in pump and motor technology. This proactive approach will optimize performance and minimize costs over the long term.

Global Market Trends: The Rise of Chinese Export Strength in Machinery

The global machinery market is witnessing a significant shift, driven by the rise of Chinese export strength. According to a report by the International Trade Centre, China accounted for nearly 30% of global machinery exports in 2022, solidifying its position as a powerhouse in this sector. This surge is largely fueled by China's comprehensive investments in advanced manufacturing technologies and its commitment to enhancing production efficiency across various industries.

As global supply chains increasingly rely on reliable machinery, the demand for high-quality pumps and motors is also on the rise. The Machinery and Equipment Industry Association reported that the market for industrial pumps and motors is expected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2028. This growth highlights not only the importance of reliable machinery in maximizing supply chain efficiency but also the dominance of Chinese manufacturers who are equipped with the technological edge and cost advantage to meet this rising demand. As businesses strive for efficiency, leveraging Chinese-exported machinery will be key in driving operational excellence.

Case Studies: Successful Integration of Pumps and Motors in Supply Chains

In today's global supply chains, the integration of advanced pumps and motors has proven to be a game-changer for operational efficiency. Case studies illustrate how companies leveraging high-performance pumps and motors can significantly streamline their processes, reduce energy consumption, and enhance productivity. For instance, in the agricultural sector, the application of renewable energy-powered pumps not only optimizes irrigation but also cuts costs. By adopting solar and wind solutions, producers harness clean energy to power their operations, showcasing a dual benefit of sustainability and efficiency.

In today's global supply chains, the integration of advanced pumps and motors has proven to be a game-changer for operational efficiency. Case studies illustrate how companies leveraging high-performance pumps and motors can significantly streamline their processes, reduce energy consumption, and enhance productivity. For instance, in the agricultural sector, the application of renewable energy-powered pumps not only optimizes irrigation but also cuts costs. By adopting solar and wind solutions, producers harness clean energy to power their operations, showcasing a dual benefit of sustainability and efficiency.

Another compelling example is found within the electric vehicle industry, where electric motors are crucial for performance and energy management. Successful integration of tailored motors in manufacturing processes can lead to faster assembly lines and improved product reliability. As companies strive to meet escalating global demands, the role of innovative pumping and motor systems becomes increasingly evident. This strategic adoption not only supports efficiency but also aligns with broader renewable energy goals, ultimately contributing to a more sustainable future for supply chains worldwide.