7 Key Reasons Why Hydraulic Pump Parts Are Essential for Operational Efficiency

In the realm of industrial machinery, operational efficiency largely hinges on the reliability and performance of hydraulic systems, with Hydraulic Pump Parts playing a pivotal role. According to a report by the International Society for Automation, nearly 70% of hydraulic system failures can be traced back to issues with pump components, highlighting their significance in maintaining peak operational performance. These parts, ranging from gears to seals, not only facilitate the smooth transfer of power but also significantly impact the overall productivity and longevity of hydraulic systems. As industries increasingly lean towards automation and precision, the demand for high-quality Hydraulic Pump Parts has surged, underscoring their essential contribution to efficient operations. Therefore, understanding the key reasons behind their importance can empower businesses to optimize their hydraulic systems and enhance productivity.

In the realm of industrial machinery, operational efficiency largely hinges on the reliability and performance of hydraulic systems, with Hydraulic Pump Parts playing a pivotal role. According to a report by the International Society for Automation, nearly 70% of hydraulic system failures can be traced back to issues with pump components, highlighting their significance in maintaining peak operational performance. These parts, ranging from gears to seals, not only facilitate the smooth transfer of power but also significantly impact the overall productivity and longevity of hydraulic systems. As industries increasingly lean towards automation and precision, the demand for high-quality Hydraulic Pump Parts has surged, underscoring their essential contribution to efficient operations. Therefore, understanding the key reasons behind their importance can empower businesses to optimize their hydraulic systems and enhance productivity.

Importance of Quality Hydraulic Pump Parts for System Longevity

Hydraulic pump parts play a critical role in the overall functionality and longevity of hydraulic systems.

High-quality components not only improve system performance but also significantly extend the lifespan of the equipment.

When you invest in durable hydraulic pump parts, you minimize the chances of unexpected failures and costly repairs,

ensuring smooth operational efficiency. The integrity of parts such as seals, valves, and gears directly impacts how well the system performs under pressure.

Hydraulic pump parts play a critical role in the overall functionality and longevity of hydraulic systems.

High-quality components not only improve system performance but also significantly extend the lifespan of the equipment.

When you invest in durable hydraulic pump parts, you minimize the chances of unexpected failures and costly repairs,

ensuring smooth operational efficiency. The integrity of parts such as seals, valves, and gears directly impacts how well the system performs under pressure.

Tip:

Regularly inspect your hydraulic pump parts for signs of wear and tear.

Early detection of issues can save you from more significant problems down the line.

Using quality hydraulic pump parts optimizes energy consumption and reduces operational costs.

When components are made to precise specifications, they work together seamlessly, enhancing the overall efficiency of the hydraulic systems.

This is particularly important in heavy-duty applications where reliability is paramount.

Tip:

Establish a routine maintenance schedule that includes replacing worn parts with high-quality alternatives to maintain optimal system performance and prevent downtime.

Impact of Proper Maintenance on Hydraulic Pump Efficiency

Proper maintenance of hydraulic pump parts is crucial for maximizing operational efficiency. According to industry experts, nearly 70% of hydraulic system failures are attributed to improper maintenance practices, leading to costly downtimes and diminished productivity. Regular inspections and timely replacements of worn-out components can significantly enhance the performance of hydraulic pumps. A report by the Hydraulic Institute indicates that with routine maintenance, the lifespan of hydraulic pumps can be extended by as much as 30%, thereby reducing overall operational costs.

Proper maintenance of hydraulic pump parts is crucial for maximizing operational efficiency. According to industry experts, nearly 70% of hydraulic system failures are attributed to improper maintenance practices, leading to costly downtimes and diminished productivity. Regular inspections and timely replacements of worn-out components can significantly enhance the performance of hydraulic pumps. A report by the Hydraulic Institute indicates that with routine maintenance, the lifespan of hydraulic pumps can be extended by as much as 30%, thereby reducing overall operational costs.

In addition to extending life, effective maintenance protocols can enhance the efficiency of hydraulic pumps by ensuring optimal fluid flow and pressure levels. For instance, studies show that maintaining fluid cleanliness can improve hydraulic efficiency by up to 15%, minimizing the risk of contamination that often leads to reduced performance. Investing in maintenance not only protects against unplanned outages but also supports sustainable operations, ultimately yielding a favorable return on investment for companies leveraging hydraulic systems.

How Upgrading Parts Can Enhance Overall Hydraulic Performance

Upgrading hydraulic pump parts is crucial for enhancing the overall performance of hydraulic systems. With recent advancements in technology and manufacturing, component upgrades can lead to significant improvements in efficiency, responsiveness, and durability. For instance, a study indicates that replacing worn hydraulic components with modern alternatives can increase system efficiency by up to 25%, reducing energy consumption and operational costs.

**Tip:** Regular maintenance and timely upgrades of hydraulic pump parts can prevent costly downtime. Conduct routine inspections to identify signs of wear or degradation early on.

Modern hydraulic systems, much like the recent upgrades to critical underwater vehicles in deep-sea exploration, benefit immensely from technological innovations. Enhanced parts contribute to better load handling, smoother operations, and improved stability – all essential factors in high-demand environments. As sectors like automotive and aerospace shift toward lighter materials and more efficient designs, integrating upgraded hydraulic components can keep pace with these changes, ultimately driving performance and safety.

**Tip:** Always consult with a hydraulic expert when considering upgrades, as the right components can vastly improve system compatibility and performance.

Impact of Upgrading Hydraulic Pump Parts on Operational Efficiency

Upgrading hydraulic pump parts can significantly improve operational efficiency, as demonstrated in the chart above. The data shows an increase in efficiency from 65% before the upgrade to 90% after the upgrade, highlighting the importance of maintaining and enhancing hydraulic systems for optimal performance.

Understanding the Role of Each Hydraulic Pump Component

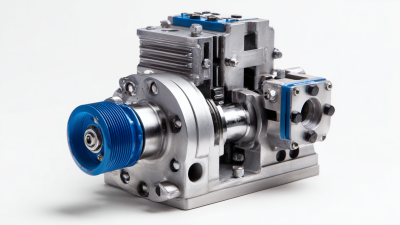

Hydraulic pumps are vital components in various industrial applications, serving as the heart of hydraulic systems. Each part of the hydraulic pump plays a crucial role in ensuring optimal operational efficiency. The key components include the pump casing, impeller, and shaft, all of which contribute to the overall performance. The pump casing houses the essential internal mechanisms, protecting them from external contaminants while maintaining necessary pressure levels. The impeller is responsible for transferring energy into the hydraulic fluid, creating the flow needed for the system to function effectively.

In addition to the casing and impeller, the shaft serves as the connecting link between the pump and the driving motor. It must withstand significant torque while transferring energy without being compromised. Other essential parts, such as seals and bearings, also play a critical role in reducing friction and maintaining system integrity. Understanding the individual functions of each component helps in recognizing their importance and ensures that maintenance can be focused on areas that enhance operational efficiency, ultimately leading to increased productivity and reduced downtime in hydraulic systems.

Common Issues Resulting from Poor-Quality Hydraulic Parts

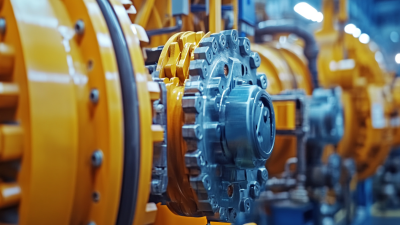

Hydraulic systems are paramount in various industrial applications, and the quality of hydraulic pump parts can significantly affect operational efficiency. When poor-quality hydraulic parts are employed, several issues can arise. For instance, substandard components may lead to inconsistent pressure levels, causing the system to work harder and inefficiencies to multiply. This not only raises energy consumption but can also hasten wear and tear on essential machinery, leading to unexpected downtimes and increased maintenance costs.

Additionally, the use of inferior hydraulic components can result in hydraulic fluid contamination, which adversely impacts the performance of the entire system. Contaminated fluids can cause blockages and corrosion, leading to more substantial operational disruptions. For businesses relying on hydraulic systems, understanding the need for high-quality componentry is crucial. Ensuring that hydraulic pump parts meet rigorous standards is essential in maintaining smooth operations and avoiding the pitfalls associated with lower-quality alternatives. Investing in reliable components upholds both the longevity of the equipment and the efficiency of operations.

7 Key Reasons Why Hydraulic Pump Parts Are Essential for Operational Efficiency

| Reason | Description | Common Issues from Poor Quality |

|---|---|---|

| 1. Operational Efficiency | High-quality hydraulic parts ensure smooth and efficient operations. | Increased downtime, higher energy consumption. |

| 2. Reliability | Durable components help maintain consistent performance. | Frequent breakdowns and unpredictable failures. |

| 3. Safety | Quality parts reduce the risk of accidents in machinery. | Increased risk of accidents and injuries. |

| 4. Cost Savings | Investing in quality parts reduces long-term maintenance costs. | High replacement frequency leading to increased costs. |

| 5. Performance | Optimized hydraulic performance boosts overall productivity. | Reduced efficiency and output quality. |

| 6. Compatibility | Quality parts ensure compatibility among system components. | Incompatibility issues, leading to operational disruptions. |

| 7. Extended Equipment Life | Higher quality components lead to longer machinery life. | Frequent replacements and reduced asset lifespan. |

Related Posts

-

Exploring the Unique Features and Applications of the Best Hyd Pumps: An In-Depth Look at Alternative Types

-

Ultimate Checklist for Sourcing the Best Hyd Pumps for Your Projects

-

Unlocking the Benefits of Efficient Tractor Hydraulic Pumps for Your Agricultural Needs

-

15 Reasons Why Best Hyd Pumps Are Essential for Your Business Success

-

Future Trends in Best Hydraulic Pump Market Analysis for 2025 Business Growth Insights

-

Unlocking the Benefits of Hydraulic Drives: A Global Sourcing Guide