How to Choose the Right Damper Actuator for Your Needs?

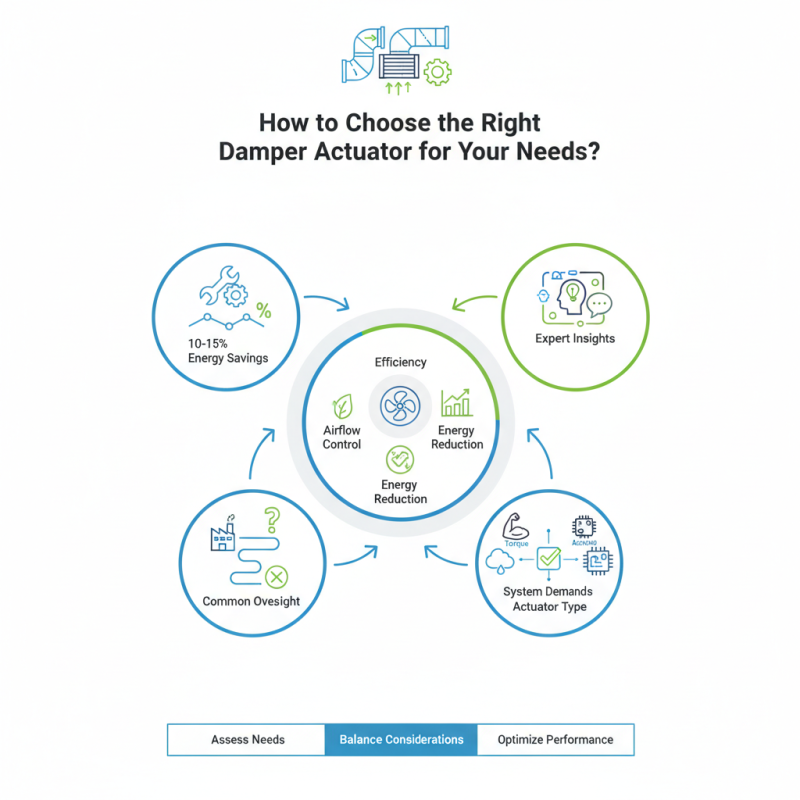

Choosing the right Damper Actuator is crucial for optimizing HVAC systems. A well-chosen actuator enhances efficiency and airflow control. According to a recent report by the International Energy Agency, proper actuator selection can lead to a 10-15% reduction in energy consumption. These figures highlight the importance of this decision.

Industry expert, Dr. Emily Carter, emphasizes, "The right damper actuator can transform system performance." Her insights reflect the significant impact these components have on overall system efficiency. However, many businesses often overlook their specific needs when selecting actuators. This oversight can lead to inefficiencies and increased operational costs.

Furthermore, with diverse applications, finding a suitable damper actuator becomes complex. Factors like torque requirements, environment, and actuator type must align with your system's demands. Neglecting these details can result in suboptimal performance. A failure to assess needs thoroughly can be detrimental in the long run. Balancing these considerations is essential for achieving desired results.

Understanding Damper Actuators: Types and Applications

Understanding damper actuators is crucial for effective HVAC system management. These devices control the flow of air through ducts, balancing temperature and pressure. There are several types available: electric, pneumatic, and hydraulic actuators. Each type serves different applications and system setups.

Electric actuators are common in commercial buildings. They offer precise control and quick response times. Pneumatic actuators are often used in larger systems, relying on air pressure. They can be simpler but may lack the responsiveness of electric options. Hydraulic actuators are powerful and suitable for heavy-duty applications. However, they require more maintenance.

Choosing the right actuator can be challenging. Consider system size, energy efficiency, and installation space. Sometimes, cost dominates the decision, leading to compromises. This can result in inefficient operation. Each project may present unique requirements. Reflecting on these factors can guide a more informed choice, ensuring optimal performance in the long run.

Damper Actuator Types and Applications

Key Factors to Consider When Selecting a Damper Actuator

When selecting a damper actuator, several key factors come into play. One of the most critical aspects is the actuator’s torque rating. This determines the amount of force it can exert. Ensure it matches the specific resistance of your dampers. A mismatch can lead to inefficiency or even damage.

Next, consider the actuator’s control method. Options can vary from electric to pneumatic. Choose the one that suits your system best. Electric actuators offer precision and ease of use. However, pneumatic models can be more powerful in certain settings. Think about your particular environment and energy sources available.

Lastly, pay attention to the actuator's response time. Some applications may require quick adjustments, while others can afford delays. Evaluate how speed impacts your overall system performance. Take the time to assess your specific needs. The right choice might not always be the most obvious or straightforward.

How to Choose the Right Damper Actuator for Your Needs?

| Parameter | Description | Impact on Selection |

|---|---|---|

| Torque Requirements | The amount of torque needed to operate the damper efficiently. | Determine the actuator strength necessary for application. |

| Voltage Supply | The electrical voltage required for the actuator to function. | Ensure compatibility with existing electrical systems. |

| Control Type | Type of control system (e.g., digital, analog) the actuator supports. | Affects integration with building management systems. |

| Environment | Conditions where the actuator will operate (temperature, humidity, etc.). | Choose materials and features that resist environmental factors. |

| Size and Space | Dimensions of the actuator and available installation space. | Ensure the actuator fits in designated mounting areas. |

Performance Specifications: Torque, Speed, and Control Options

When selecting a damper actuator, consider performance specifications like torque, speed, and control options. Torque is crucial for your application. It determines how much force the actuator can exert. Ensure that the selected actuator can handle the load it will be controlling. Insufficient torque can lead to poor performance and undesired outcomes.

Speed is another important factor. The right actuator should enable quick response times. If the actuator is too slow, it might not adjust dampers efficiently. Different applications require varying speeds. Evaluate how fast your system needs to react and choose accordingly.

Tips: Assess the environment where the actuator will be used. Check for temperature extremes or moisture. These factors can impact performance. Consider the control options. Options like manual, automatic, or remote control can enhance usability. Make sure to weigh the benefits of each against your specific needs.

Finding the perfect balance between these specifications can be challenging. It's not always straightforward. Reflect on the real-world demands of your application. Understand how these choices affect overall system functionality.

Industry Standards and Regulations Governing Damper Actuators

When selecting damper actuators, it's crucial to consider industry standards and regulations. The American National Standards Institute (ANSI) and the National Electrical Manufacturers Association (NEMA) provide guidelines that ensure safety and efficiency. According to a recent report by Frost & Sullivan, compliance with these standards can improve system reliability by 30%. These results highlight the importance of using actuators that meet or exceed prescribed regulations.

Moreover, the International Organization for Standardization (ISO) has established norms for performance and environmental sustainability. For instance, ISO 9001 emphasizes quality management systems, which can enhance actuator performance. Regulators continually update these standards as technology advances. However, many manufacturers struggle to keep up with compliance. Failures can lead to inefficiencies, costly downtime, and safety hazards. Regular audits and adherence to these regulations are essential, but some companies overlook this.

Finding the right actuator means understanding these standards. Despite their best efforts, many businesses fail to see significant improvements. Sometimes, further training on new guidelines is necessary. Hence, choosing the right damper actuator entails ongoing education and commitment to quality standards. This will ensure that systems operate at optimal levels and comply with global expectations.

Cost Analysis: Budgeting for Quality and Longevity in Your Selection

When selecting a damper actuator, budgeting is crucial. A common mistake is focusing only on upfront costs. Higher quality actuators may have a higher price tag but often offer greater longevity. This can save money in the long run. Investing a bit more now can lead to fewer replacements and repairs later.

Tips: Always consider the environment the actuator will operate in. Harsh conditions can lead to quicker wear and tear. A more durable actuator may be worth the investment. Additionally, look for models with good warranties. This often indicates a manufacturer’s confidence in their product.

Don’t overlook maintenance costs. They can add up over time. A cheaper actuator may require more frequent servicing. This can negate initial savings. It’s essential to think long-term when making your choice. Evaluate both the purchase price and the potential ongoing costs.